Elevator Functions:

OMNI Green Motherboard

Elevator Functions: OMNI Green Motherboard

Some Remarc Vending machines come with an elevator to facilitate safe delivery of fragile items from any point in the machines. These elevators can improve customer experience, but introduce more moving parts to a machine that can need troubleshooting or repair. This guide will walk you through the component's of a machine's elevator, some common errors that can occur, and how to manipulate the elevator components if needed.

Elevator Components

Product Door

The product door is locked by default and only unlocks after a successful vend, after which is locks again. This is to prevent customers from being able to reach into a machine while it is vending. The product door is held in place by two pins, one on each side of the door.

Diaphragm

Sometimes called a "separator board" or a "baffle plate", the diaphragm is a piece of metal that slides in and from underneath the bottom tray to prevent customers from reaching up into the machine while the product door is unlocked, but allow the elevator to move up and down when it is locked.

Elevator

The elevator moves up to the height of a selected product as it vends to eliminate any damage that would occur from falling. Once a product is in the elevator, sensors on both sides confirm the vend as successful, and the elevator returns to the bottom of the machine to deliver product to customers.

Common Issues

During operation, the vending machine may give an error called a Lift Error (shown as "Lift N" where "N" is a number). This indicates an issue with one of the above mentioned elevator components. Here is a light guide on the most common errors and their fixes, but call Remarc Vending technical support if these solutions do not resolve the issue, or if a Lift Error is encountered that is not covered in this section.

- Product Door: The product door has three sensors, one to detect whether or not the door is closed, and one on each side to confirm that the locking pin is in place for that side. All three of these sensors are checked when the machine initially powers on, as well as when a vend begins. If any issues are detected, the machine will repeatedly try to lock and unlock the door, then give a Lift Error, most commonly Lift 1 or Lift 2.

- To resolve: Ensure there is nothing blocking the locking pins on either side of the product door such as vinyl, foam, or anything a customer may have stuck in there. Make sure the product door is closing all of the way and not being propped up by something, such as a product stuck in the elevator or something stuck behind the product door.

- To resolve: Ensure there is nothing blocking the locking pins on either side of the product door such as vinyl, foam, or anything a customer may have stuck in there. Make sure the product door is closing all of the way and not being propped up by something, such as a product stuck in the elevator or something stuck behind the product door.

- Diaphragm: The diaphragm has a sensor on the front and back of the sliding mechanism behind the metal plate, one confirms that the plate has opened all the way, and the other confirms that the plate has closed. If a command is sent to open or close the diaphragm and one of these two sensors does not confirm the diaphragm has moved correctly, the machine will give a Lift Error, most commonly Lift 32.

- To resolve: Check that the diaphragm is not getting caught on something while attempting to move, such as product, wires behind trays, or occasionally the elevator itself can block the diaphragm from opening if it is not returned to its home position before a vend starts.

- To resolve: Check that the diaphragm is not getting caught on something while attempting to move, such as product, wires behind trays, or occasionally the elevator itself can block the diaphragm from opening if it is not returned to its home position before a vend starts.

- Elevator: There are a host of issues that can occur with the elevator, each of which will give a Lift Error; however, the most common and simplest to resolve is Lift 3 (or Lift 8 on a Red Motherboard machine). Lift 3 occurs when the machine attempts to move the elevator, but detects no movement, indicating something is blocking the elevator from moving.

- To resolve: Remove any product from inside of and underneath the elevator. Make sure the elevator has not become caught on any part of the machine, such as the tabs holding the trays in place, the diaphragm, or any products sticking out of the trays. Ensure nothing is in either track on the sides of the elevator that would prevent the smooth motion of the belt operating the elevator. Ensure the elevator is not crooked on its tracks.

If you continue to experience any Lift Errors even after following these steps, please reach out to Remarc Vending technical support when you are next at the machine for further assistance in troubleshooting and resolving the issue(s).

Moving/Testing Elevator Components

There may be times where the elevator components may need to be moved to test that they are working correctly or to get them out of the way of other tests or procedures (such as cleaning the cooling deck). This guide will explain how to use these components. To access the elevator tools, follow these steps:

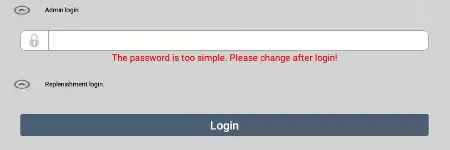

Log in to Admin Login

Tap Setup Tool

The Setup Tool Menu

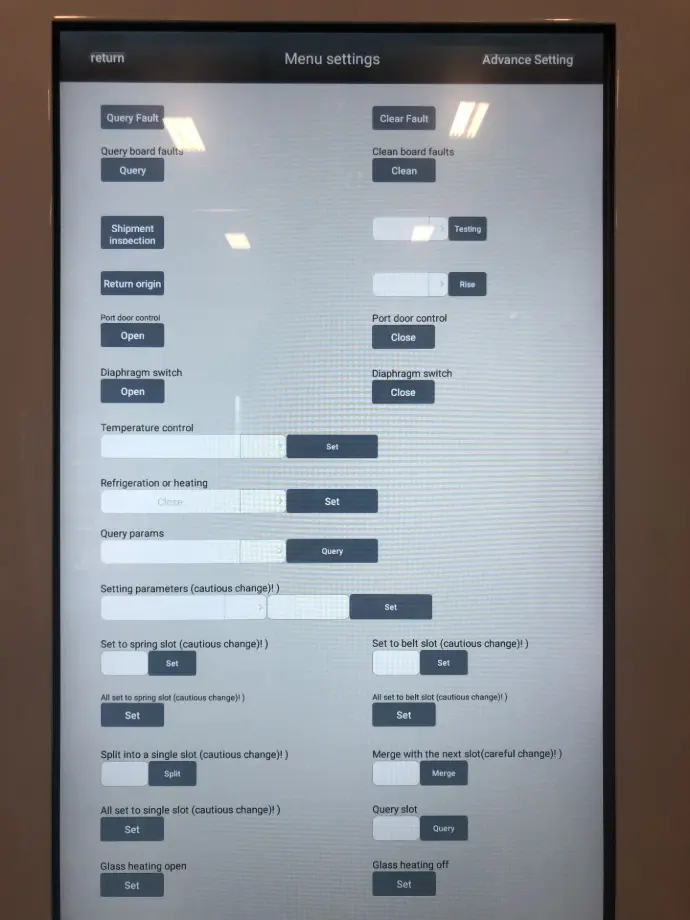

Query board faults

Tap the "Query" button to see if any errors are affecting the elevator system. "Normal" will appear to the right if there are no errors, and the Lift Error will appear instead if there is an error. This can be used to communicate the error with Remarc technical support.

Clean board faults

If an error has occurred, no elevator components will move until the error has been cleared out. Tap the "Clean" button to do this. Note: If whatever is causing the error has not been fixed, the error will be thrown again after another attempt.

Return origin

This button will send the elevator back to the bottom of the machine and close the diaphragm. This should be done after any testing is completed.

Rise

Tap the arrow to the left of the rise button to select a tray height (1 is the top tray, 2 is the tray below it, etc.), then tap the "Rise" button to move the elevator to the desired tray. This can be used to confirm it is moving to the correct height, as well as to get the elevator and diaphragm out of the way to clean the cooling deck.

Port door control Open/Close

The "Open" button will unlock the product door and allow it to be opened. The "Close" button will attempt top lock the product door to prevent it from being opened.

Diaphragm switch Open/Close

The "Open" button will slide the diaphragm below the bottom tray to move it out of the way for the elevator to move up and down. The "Close" button will extend the diaphragm to cover the elevator and prevent any customers from being able to reach up into the machine.

Do not use other functions on this menu unless directed to in another guide or by a Remarc Vending technician.

Didn't find what you were looking for?

Feel free to reach out to our esteemed technical support department to answer any questions you may have over the phone at (719)-301-4648 or over email at tech@remarcvending.com or you can fill out a support ticket to the right.

Didn't find what you were looking for?

Feel free to reach out to our esteemed technical support department to answer any questions you may have over the phone at (719)-301-4648 or over email at tech@remarcvending.com or you can fill out a support ticket to the right.